|

| |

| 1. Application : Identify the objectives of your mixing, what you want to achieve and what to avoid. |

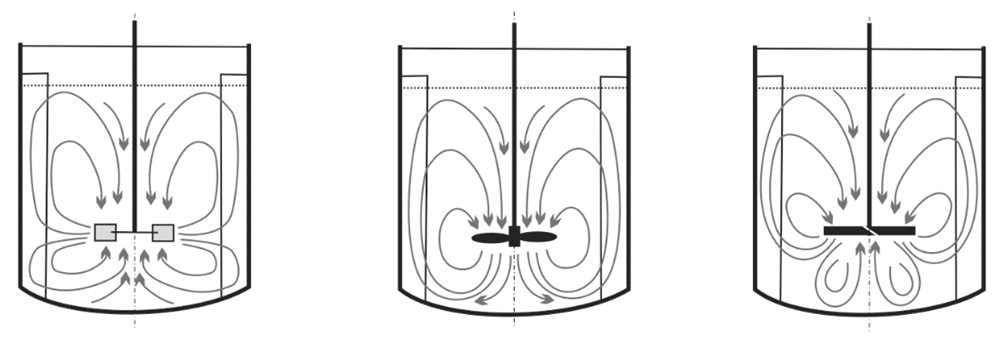

| 2. Flow |

|

| 3. Vessel diameter : The size of vessel used for mixing will determine the diameter of the impeller. |

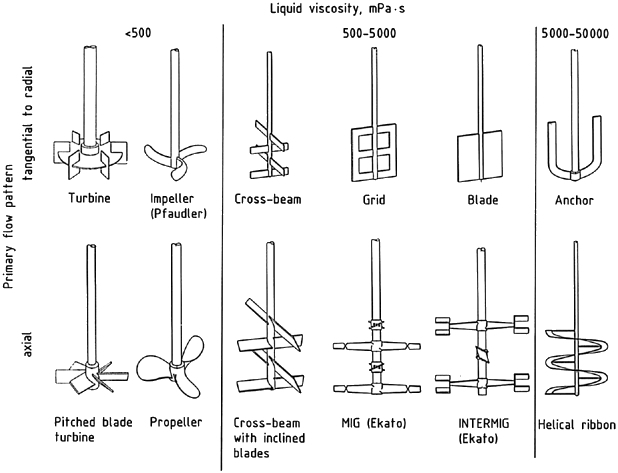

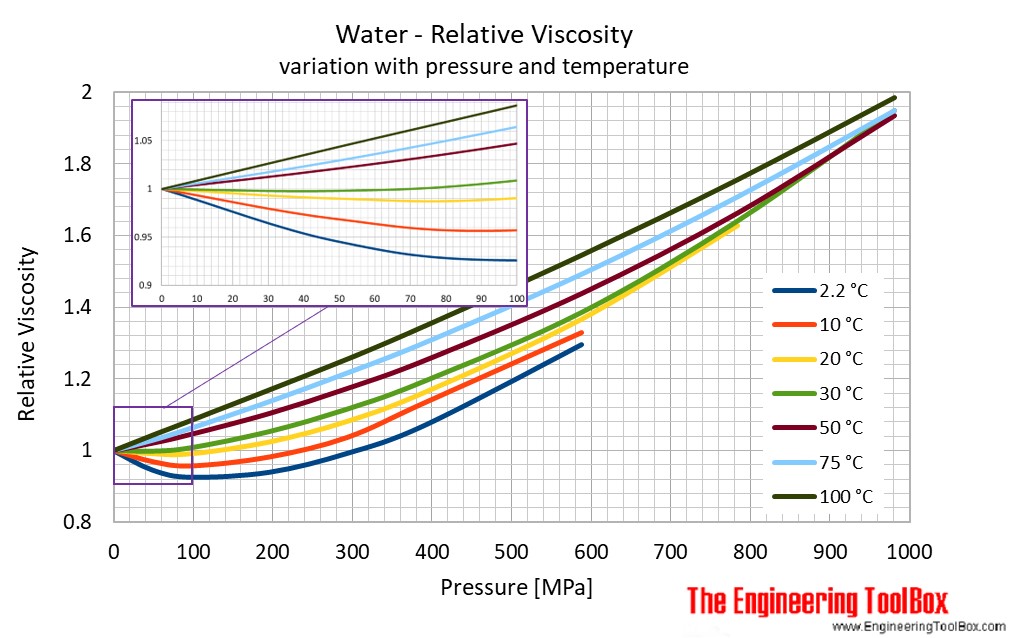

| 4. Viscosity |

|

| 5. Compatibility with stirring equipment : Confirm the diameter of the shaft to be used fits the chuck of the overhead stirrer. |

| 6. Material : Stirring impellers are most commonly manufactured in stainless steel as it is low maintenance, easy to clean, and resistant to corrosion and most chemical reactions. |

| 7. Specialty : There are some specialty styles that work well for some applications. |

| |

|

| |

Unit conversion

Viscosity Dynamic, Absolute

centipoise [cP], gram/(centimetre second) [g/(cm s)] = poise [P], kilogram/metre second [kg/m s]=newton second/square metre [N s/m2]= pascal second [Pa s], pound/(foot hour) [lb/(ft h)], pound/(foot second) [lb/(ft s)], reyn [reyn]

- 1 cP = 0.001 Pa s = 0.01 P = = 0.01 g/(cm sec) = 6.72197x10-4 lb/(ft s) = 2.4191 lb/(ft h)

- 1 lb/(ft h) = 0.00027778 lb/(ft s) = 0.00041338 Pa s = 0.0041338 P = 0.41338 cP

- 1 lb/(ft s) = 3600 lb/(ft h) = 1.48816 Pa s = 14.8816 P = 1488.16 cP

- 1 kg/(m s ) = 1 (N s)/m2 = 1 Pa s = 10 P = 1000 cP = 0.672197 lb/(ft s) = 2419.09 lb/(ft h)

- 1 (N s)/m2 = 1 kg/(m s ) = 1 Pa s = 10 P = 1000 cP = 0.672197 lb/(ft s) = 2419.09 lb/(ft h)

- 1 P = 1 g/(cm s) = 0.1 Pa s = 100 cP = 0.067197 lb/(ft s) = 241.909 lb/(ft h)

- 1 Pa s = 1 kg/(m s) = 1 (N s)/m2 = 10 P = 1000 cP = 0.672197 lb/(ft s) = 2419.08 lb/(ft h) = 0.00014504 reyn

- 1 reyn = 6894.76 Pa s

|

| |

Viscosity Kinematic

centistoke [cSt] = square millimetre/second [mm2/s], square foot/hour [ft2/h], square foot/second [ft2/s], square inch/second [in2/s], square metre/hour [m2/h], square metre/second [m2/s], stoke [St] = square centimetre/second [cm2/s]

- 1 cm2/s = 1 St = 100 mm2/s = 100 cSt = 1x10-4 m2/s = 0.36 m2/h = 1.07639x10-3 ft2/s = 3.875008 ft2/h = 0.1550003 in2/s

- 1 cSt = 1 mm2/s = 0.01 St = 1x10-6 m2/s = 0.0036 m2/h = 1.07639x10-5 ft2/s = 0.03875008 ft2/h = 0.001550003 in2/s

- 1 ft2/h = 2.7778x10-4 ft2/s = 0.04 in2/s = 2.58064x10-5 m2/s = 0.09290304 m2/h = 25.8064 cS = 0.258064 St

- 1 ft2/s = 3600 ft2/h = 144 in2/s = 0.09290304 m2/s = 334.451 m2/h = 92903.04 cSt = 929.0304 St

- 1 in2/s = 0.0069444 ft2/s = 25 ft2/h = 0.00064516 m2/s = 2.322576 m2/h = 645.16 cSt = 6.4516 St

- 1 m2/h = 1/3600 m2/s = 2.7778x10-4 m2/s = 2.7778 cm2/s = 277.78 mm2/s = 277.78 cSt = 2.7778 St = 0.00298998 ft2/s = 10.7639 ft2/h = 0.430556 in2/s

- 1 m2/s = 3600 m2/h = 1x104 cm2/s = 1x104 St = 1x106 mm2/s = 1x106 cSt = 10.7639 ft2/s = 38750.08 ft2/h = 1550003 in2/s

- 1 mm2/s = 1 cSt = 1x10-6 m2/s = 0.0036 m2/h = 0.01 cm2/s = 0.01 St = 1.07639x10-5 ft2/s = 0.03875008 ft2/h = 0.001550003 in2/s

- 1 St = 1 cm2/s = 100 cSt = 100 mm2/s = 1x10-4 m2/s = 0.36 m2/h = 1.076x10-3 ft2/s = 3.875008 ft2/h = 0.1550003 in2/s

|

| |